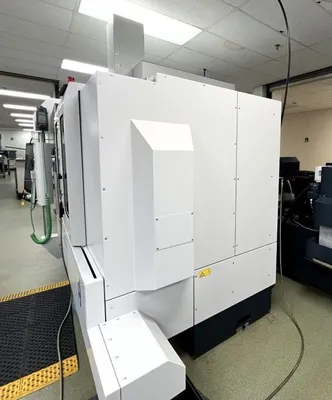

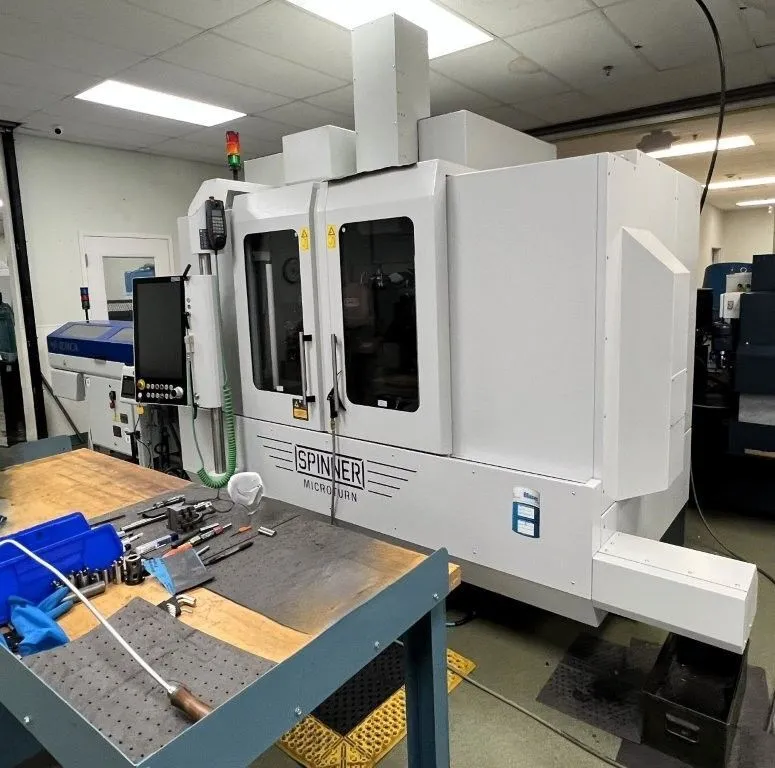

Spinner MICROTURN 52 LTBS

Sub-Micron Turn Mill Center with Y / B-Axis and Twin Spindles

AUTOMATION READY - MC0122

Less than 300 hours

No bar feed

Tools and probes included—for all 3 spindles? BMT 45 Probe would stay. No tooling

Chucks etc. included Yes

Coolant: used Water Based

What kind of facility is it in? R and D for performance parts for injector and turbos

Specifications

Work Area:

Swing Diameter: 23.9 in (608 mm)

Turning Diameter (max): 5.9 in (150 mm)

Turning Length(max): 9.8 in (250 mm)

Travels:

X: 23.6 in (600 mm)

Z:13.8 in (350 mm)

Y1 Turret: +/- 1.9 in (50 mm)

Y2 Milling Spindle: +/- 1.9 in (50 mm)

B Rotary: 180 degrees

Feedrate:

Rapid Traverse X: 944.8 ipm (24 m/min)

Rapid Traverse Y: 590.6 ipm (15 m/min)

Rapid Traverse Z: 944.8 ipm (24 m/min)

Spindle #1 Left / #2 Right:

Liquid cooled motorized spindle with C-axis servo drive and encoder for synchronous machining.

Spindle Bore Capacity: 52mm (2.0 in)

Speed: 5,200 rpm

Performance (S6 40%): 22.1 hp (16.5 kW)

Torque (S6 40%): 81.1 ft-lb (110 Nm)

Spindle Nose: DIN 55026-A6

B-Axis Milling Spindle:

Speed (max): 12,000 rpm

Performance (S6 40%): 12 hp (9 Kw)

Torque (S6 40%): 15.4 ft-lbs (21 Nm)

Swivel Angle: +/- 180 degrees

Positional Measurement: Rotary Encoder

Clamping: Hydraulic

Turret:

Stations: 12 / BMT45

Live Tooling Speed: 8,000 rpm

Performance (S3 25%): 5.8 hp (4.3 kW)

Torque (S3 25%): 10 ft-lb (13.6 Nm)

Tool Magazine:

Station Quantity: 72

Holder Type: HSK40

Tool Length (max): 4.1 in (105 mm)

Tool Diameter (max): 3.5 in (88 mm)

Tool Diameter (max) - Adj Pocket Empty: 3.9 in (100 mm)

Size & Electrical:

Technical design according to CE standards.

Machine Dimensions: 119.3 in (3030 mm) x 111.8 in (2840 mm) x 113.8 in (2890 mm)

Machine Weight: 16,976 lbs (7,700 kg)

Operating Voltage: 3 x 400V (+/-10%)

Main Frequency: 60 Hz (+/- 2%)

Electrical connection: TN network (5-wire)

Standard Equipment

• 72-station tool magazine mounted on top of the machine

• Hydraulic spindle brake on spindle 1

• Hydraulic spindle brake on spindle 2

• Spindle rinsing on spindle 1 (switchable between coolant or compressed air)

• Spindle rinsing on spindle 2 (switchable between coolant or compressed air)

• CNC Clamping Force Setting on Spindle 1 - recommended for convenient setting of clamping force from the CNC program, or on the screen.

• CNC Clamping Force Setting on Spindle 2 - recommended for convenient setting of clamping force from the CNC program, or on the screen.

• Linear tool slide with coolant supply

• Signal lamp

• Rear exit chip conveyor - includes feed pump rated at 5 bar at 20l/min or 3.7 bar at 83l/min

• High pressure coolant system with additional 61 gallon (230 liter) tank. Maximum 319 psi (22 bar)

• Renishaw tool probe for measuring tools in the X/Y/Z axis

• Preparation for mist collector unit

• Automatic operator door that opens at the end of the program and closes with the start. Includes necessary safety technology. Suitable for manual loading or automation access.

• UNIROB universal robot interface via a common plug on the machine control cabinet with the following signals:

• Safety signals (emergency stop/door signals, etc.)

• Standard signals via Profinet PN bus coupler on RJ45 module. Otherwise according to the Unirob-V2021 functional description

CNC Control System

SIEMENS 840D control with the following basic scope:

• SPINNER - SPIOS 24" Touch Control Panel for I4.0 applications

• Engraving cycles

• 24" liquid crystal color flat panel display with Multi touch functionality

• User memory 2 GByte

• 15 zero offsets

• 1 free USB interface

• Standard Ethernet interface

• PRIMARY LANGUAGE: German

• SECOND LANGUAGE: English

We use cookies to improve your experience. Privacy Policy.