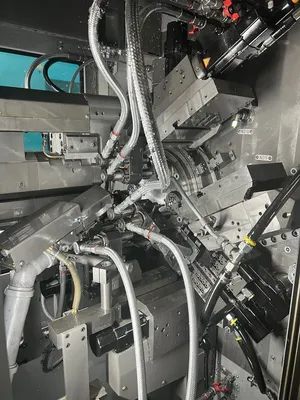

INDEX MS 16 Plus

CNC Multi-Spindle CNC Screw Machine

Mfd: 2020

Control: INDEX C200 SolutionLine

6-Spindle CNC Multi-Spindle Automatic

Maximum Bar Diameter: 22mm (0.866")

Single NCU with PCU, HSP Individual Drive System

2 Syncrons

• Dual Operator Panels with 18.5" Flat Screen Displays

• Second Display with Touchscreen Technology

• Smartlight LED Signal Light

• EC Conformity Certificate

SLIDE CONFIGURATIONS:

Spindle Position 1:

• Slide 1.1: X-Axis and Z-Axis NC-controlled

• Slide 1.2: X-Axis fixed, Z-Axis NC-controlled

Spindle Position 2:

• Slide 2.1: X-Axis fixed, Z-Axis NC-controlled

• Slide 2.2: X-Axis and Z-Axis NC-controlled

Spindle Position 3:

• Slide 3.1: X-Axis and Z-Axis NC-controlled

• Slide 3.2: X-Axis NC-controlled, Z-Axis fixed

Spindle Position 4:

• Slide 4.1: X-Axis NC-controlled, Z-Axis fixed

• Slide 4.2: X-Axis and Z-Axis NC-controlled

Spindle Position 5:

• Slide 5.1: Z-Axis NC-controlled

• Slide 5.2: X-Axis and Z-Axis NC-controlled

Spindle Position 6:

• Slide 6.1: Z-Axis NC-controlled

• Slide 6.2: X-Axis and Z-Axis NC-controlled

TOOLING & WORKHOLDING:

• Set of 6 BZ Collet Holders for Main Spindles (Max Clamping Diameter: 22mm)

• Mechanical Device for Changing Collets at Main Spindle

• 2 x Hainbuch Spanntop Axfix D22 for Synchronous Spindles

MATERIAL HANDLING:

• IEMCA SIR MS16plus/33/P Side Loader

• 50Hz Flat Magazine Loader

• Diameter Range: 9-13-19-26mm

• Bar Length: 3,300mm (130")

• Material Storage: 200mm Loading Surface

• Additional Storage Chain for 20 Bars

• Profibus-DP-Slave Interface

• Additional Bar End Sensor on IEMCA SIR

• Set of 6 Material Pushers for D14-16mm

• Set of 6 Guide Intermediate Tubes D19mm

• UNIMAG Interface for Bar Loading Magazine Connection

SYNCHRONOUS STATIONS:

Position 5.1 & 6.1:

• Synchronous Device with Workpiece Ejection

• Spring Return, Adjustable for 6mm, 12mm, 18mm, or 35mm Stroke

• Coolant Supply through Synchronous Spindle

BACKWORKING CAPABILITIES:

• Backworking Unit at Position 5.2 with Two Fixed Tool Holders D15

• Backworking Unit at Position 6.2 with Two Fixed Tool Holders D15

PART DISCHARGE:

• Pneumatic Part Discharge from Spindle Position 5 to Right

• Pneumatic Part Discharge from Spindle Position 6 to Right

• Electrical Preparation for External Conveyor from Position 6

ADDITIONAL DRIVES:

• Polygon and Thread Milling Unit for Cross Slides

• Gear Ratio i=5:1

• Inductive Sensor for Reference Query

• INDEX Short Taper Mount

• Suitable for D70 Cutters

• Oil/Air Lubrication for Tool Holders (Up to 6 Units)

• Electrical Preparation for Two Additional Drives with Electronic Cam

• Electrical Preparation for 1st Material Stop Control

• Electrical Preparation for 2nd Material Stop Control

• 2 x Electrically Monitored Cutoff and Stop Holders

CONTROL FEATURES:

• NC Option for Synchronous Spindle/Polygon Turning including Electronic Cam

• Freely Programmable Interface: 16 Inputs and 16 Outputs

• Transmit/Tracyl Function for C200-4D including Cylindrical Path Milling

• Eight Configurable Control Outputs for Operating Status

• Integrated ARTIS Process Monitoring System (Motor Current Based)

• VPN Teleservice Connection

• Configurable Electrical Interface for 16 Hydraulic/Pneumatic Units via M-Functions

• Universal ChipMaster Chip Breaking Cycle

• VirtualLine Software

COOLANT & CHIP MANAGEMENT:

• Cutting Oil Required (Mineral Oil Based)

• UNICOOL-DP Standardized Communication Interface

• Hinged Belt Chip Conveyor: 570mm Discharge Height, Left Discharge, with Lift Pump

• Coolant Filtration System 50Hz

• Chip Cart without Transponder, 100 Liter Capacity

• Preparation for Central Oil Mist Extraction System

SAFETY & FIRE SUPPRESSION:

• Automatic CO2 Fire Suppression System

• Optical/Thermal Fire Detection

• CO2 Extinguisher Tank and Control Unit

• Not suitable for machining magnesium or magnesium alloys

UTILITIES:

• Four Valve Positions for NG4 Hydraulic Valves

• Three G1/8" Compressed Air Connections (6 bar)

• Machine Configured for TN Network Connection

ELECTRICAL SPECIFICATIONS:

• Nominal Power: 63 kW

• Connected Load: 75 kVA

• Nominal Current: 108 A

• Maximum Fuse: 125 A

• Mains Voltage: 400V

• Frequency: 50 Hz

We use cookies to improve your experience. Privacy Policy.