Traub TNX 65/42 Milling and Turning Center

Mfd. 2007

Serial #7060107

Commissioned in 2010

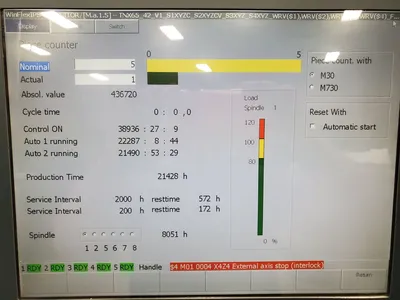

Production Hours: 21,428

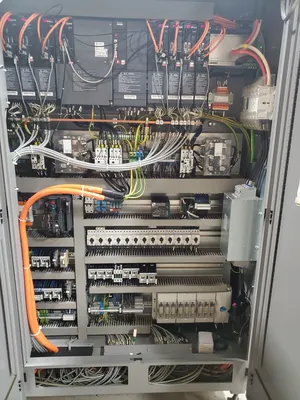

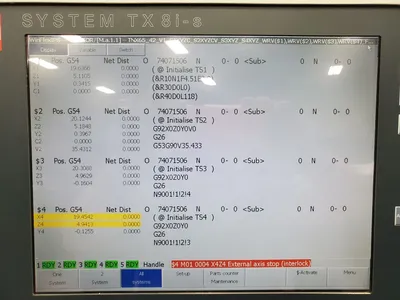

TX 8i-S control (Mitsubishi/Traub based control with Mitsubishi drives and motors)

15 CNC axis’s

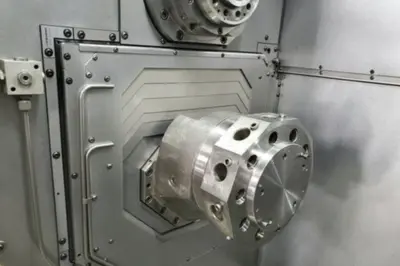

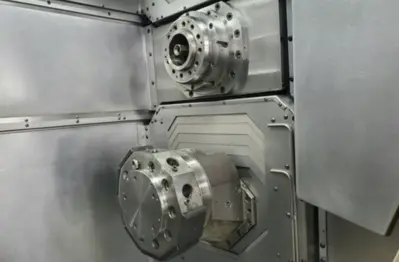

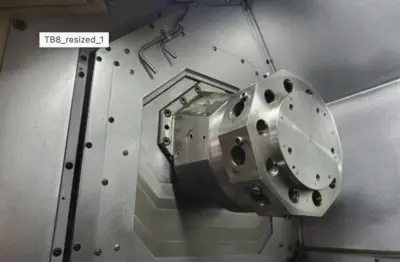

(4) X-Y-Z turrets with 10 positions each. Up to 20 tools per turret

65 mm thru hole main and sub spindle (sub spindle has coolant flush)

Foot pedal control for clamp/unclamp of spindle chucks

Servo driven gantry receiver

Hydraulic swivel w/ pneumatic finished part and bar remnant gripper

Finished part conveyor belt

RESY paper band coolant filter

Knoll Coolant tank with BKW refrigerated coolant temperature control

20 Bar High pressure and 8 Bar Low pressure coolant pumps

Knoll chip conveyor

2) Single stick turning tool holders

2) Double stick turning tool holders

1) Cut-off tool holder

1) Overdriven double radial live ER Collet tool holder

1) Overdriven radial live ER Collet tool holder

4) Radial live ER Collet tool holders

1) Radial live End Mill tool holder

1) Angle adjustable live ER Collet tool holder

2) Radial live Shell Mill tool holders

2) Axial live End Mill tool holders

6) Axial live ER Collet tool holders

43) Additional tool holders on separate list (see supplemental attachment)

Hainbuch main spindle collet chuck

Rohm sub spindle 2 jaw chuck

2 Spare sets of spare Z-axis ball screws and bearing packs.

History on this machine;

Built in 2007 commissioned/ installed in 2010

Leased machine

Ran for 6 years making rifle scope mounts

Sat idle for 1 year while being remarketed by bank

We purchased it Feb 2018

The last 2 years, undergoing extensively refurbished at our facility

Refurbish included but not limited to;

Disassembly and Removal of all panels and way covers

Very thorough and detailed steam cleaning of ALL components and machine from top to bottom

Replacement of any wore/broken hoses, cables or electrical/mechanical/hydraulic components

Replacement of ball screws and bearing packs where needed.

Replaced all servo buffer batteries

Replaced all pneumatic/hydraulic filters

Refinish or replace all large panels and the mounting hardware

Replace all 4 turret’s slideable X-Y covers

Replaced all rubber, plastic, and metal sealing band way cover wipers

Reassembly using new fasteners where needed.

Complete disassembly of coolant tank and chip conveyor components.

A very thorough and detailed steam cleaning of all components and covers to like new condition

The refurbish was done for many trouble free years of use. No expense was spared on this refurbish with many new parts. Over 500 hours just in cleaning every nook and crevice of this machine and its accessories.

We use cookies to improve your experience. Privacy Policy.